- Scalable processing from 100mL to >100L

- Perfect for both research and production

- Key applications include:

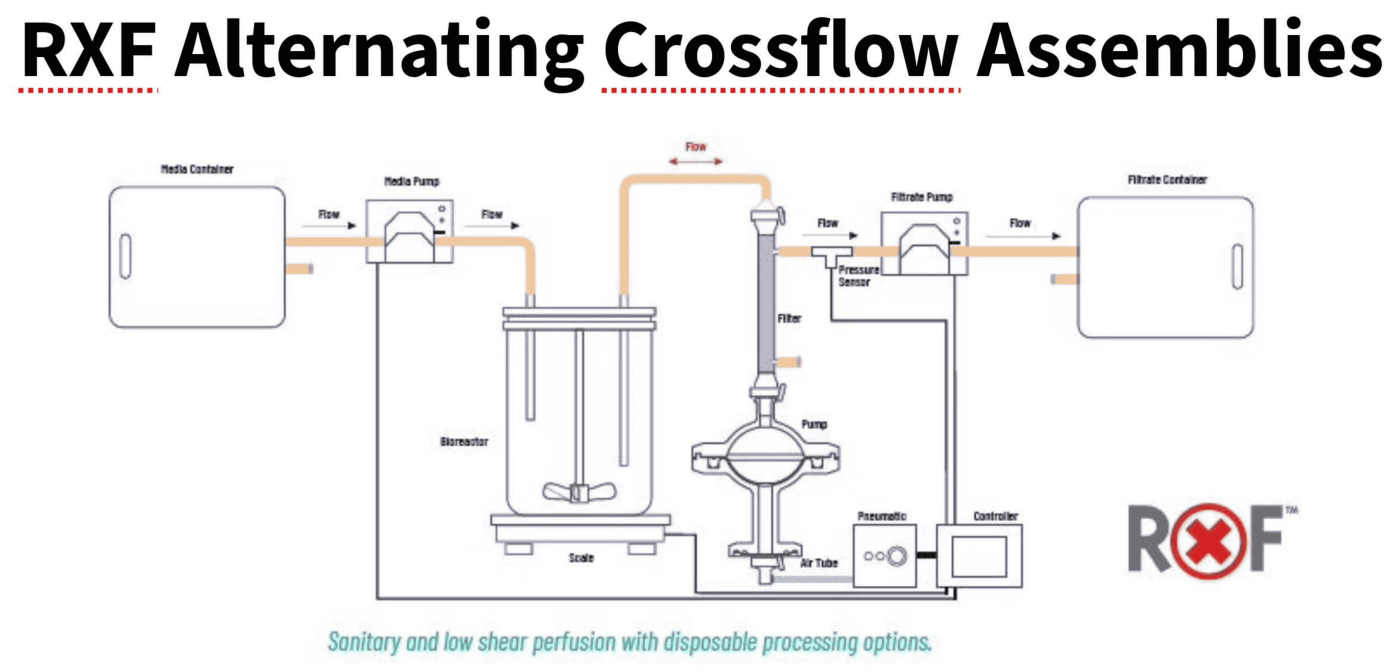

- Bioreactor perfusion with a hollow fiber filter

- N-1 perfusion process intensification

- Liquid transfer

- Liquid-liquid mixing

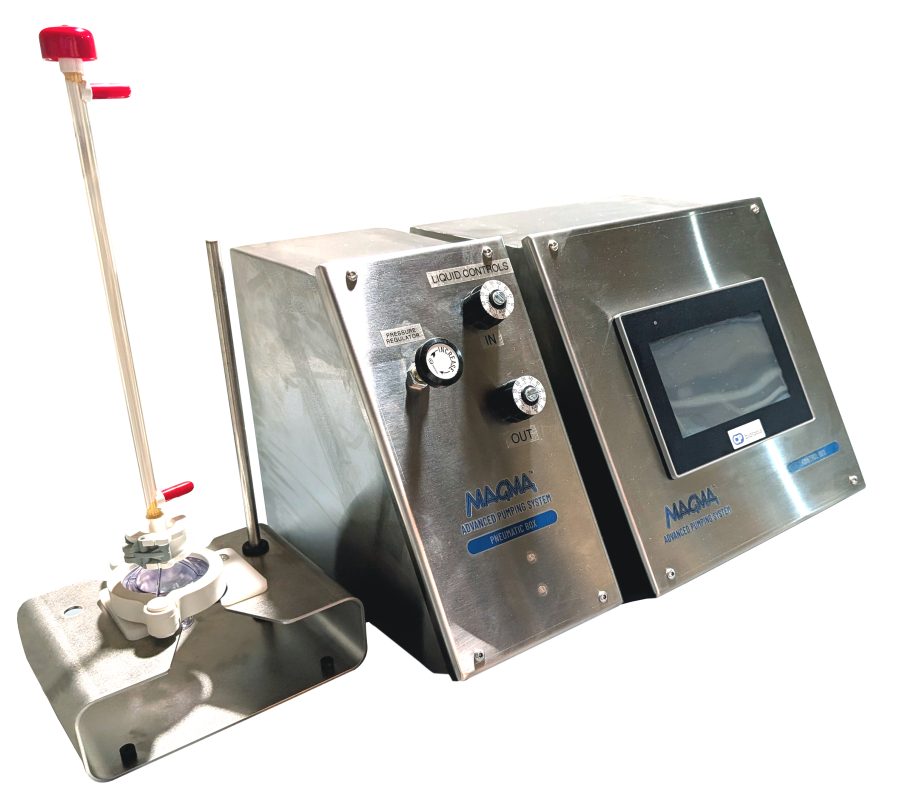

- Plug-and-play design creates an integrated system for advanced applications

- Flexible design optimizes lab space

Product Highlights

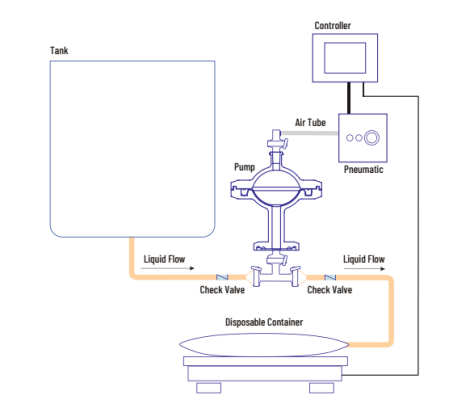

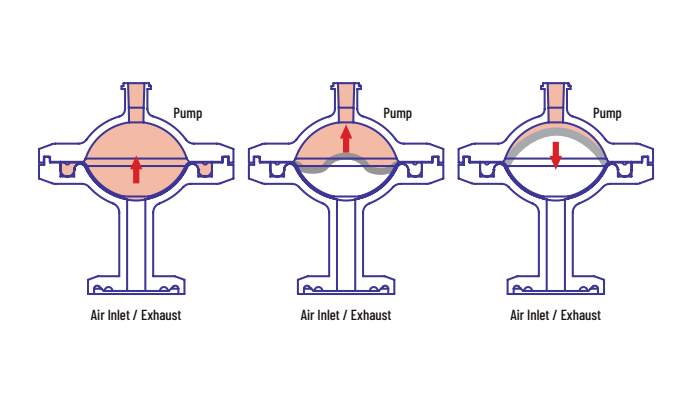

Low Shear Liquid Handling – Diaphragm pumps are low shear in the manner in which they handle fluid and fluid components. Certain pumps such as peristaltic pumps and rotary lobe pumps create pressure gradients and pinch points as the liquid flow is moved though narrow mechanical devices or pinch points. The Magma Advanced Pumping System (APS) diaphragm pump creates only enough pressure to push the liquid against back-pressure and eliminates pinch points. This can be important in applications where the liquid and/or liquid components are shear sensitive.

Smart-StopTM – After pressing the STOP button once, the pump empties the liquid and momentarily vents the air from the pump head to relieve pressure. This minimizes liquid hold-up in the pump and safely removes air pressure.

Quick-StopTM – Pressing the QUICK-STOP button immediately stops the pump in its current position. It can be useful in certain applications when you do not want the liquid hold-up to be purged.

Safety Alarms – Process conditions are monitored to detect if the pump is not operating properly and if an alarm condition occurs, a QUICK-STOP is initiated and the alarm visual and audible indicators occur.

Data Output – Data can be captured by an external computerized system via the controller Ethernet Port.

Monitoring of Process Pressures – Three PendoTECH Single-Use Pressure Sensors™ can be connected to the controller. There are user definable minimum and maximum notification settings and the control system will compare the settings to the minimum and maximum pressures since the last time the RUN button was pressed. There is a notification on the display if the running minimum drops below its setting or the maximum exceeds its setting. This is particularly useful for monitoring of the pressure in the permeate tubbing which will start to drop as the filter fouls indicating action must be taken.

Permeate Pump Integration – A permeate pump can be interfaced to the control system to be turned on/off when the controller switches between the run/stop modes either manually or by an alarm condition.

Vessel Weight Control System – A scale and a feed pump can be connected to the control system and a set-point weight entered into the control system. In the run mode, the feed pump will turn on when the scale reading drops below the set-point value.

Liquid Detector – In case of improper installation of the diaphragm or a failure condition, liquid entry through the air line to the pump controller will trigger a Quick-Stop and close a valve in the controller to minimize liquid entry to the controller and prevent liquid flowing through the controller.

Product Features

Pump and Diaphragm

Designed for Low Shear and Sterile Processing

Low Shear – Through the air inlet/exhaust sanitary fitting, air from the control system enters to push liquid from the pump and through the fitting that is connected to the process fluid. The only pressure generated is from process back-pressure. After the pump has discharged the liquid, liquid is then drawn into the pump by vacuum connected to the control system unless there is enough liquid pressure to drive liquid into the pump at the desired flow rate, then vacuum is not needed.

Sanitary – The specially designed silicone diaphragm is sealed with an industry standard sanitary clamp into the pump. It is designed for quick assembly and disassembly and the pump and diaphragm are made of materials that meet industry guidelines. All pump head materials are either stainless steel of plastic and are compatible with autoclaving, and for the plastic pump heads, with gamma irradiation.

Proven Performance – Silicone Diaphragm material is USP Class VI and all sizes tested to run > 1 million cycles (~60 days continuous use). The pump heads are proven for sterile operations with years of customer use.

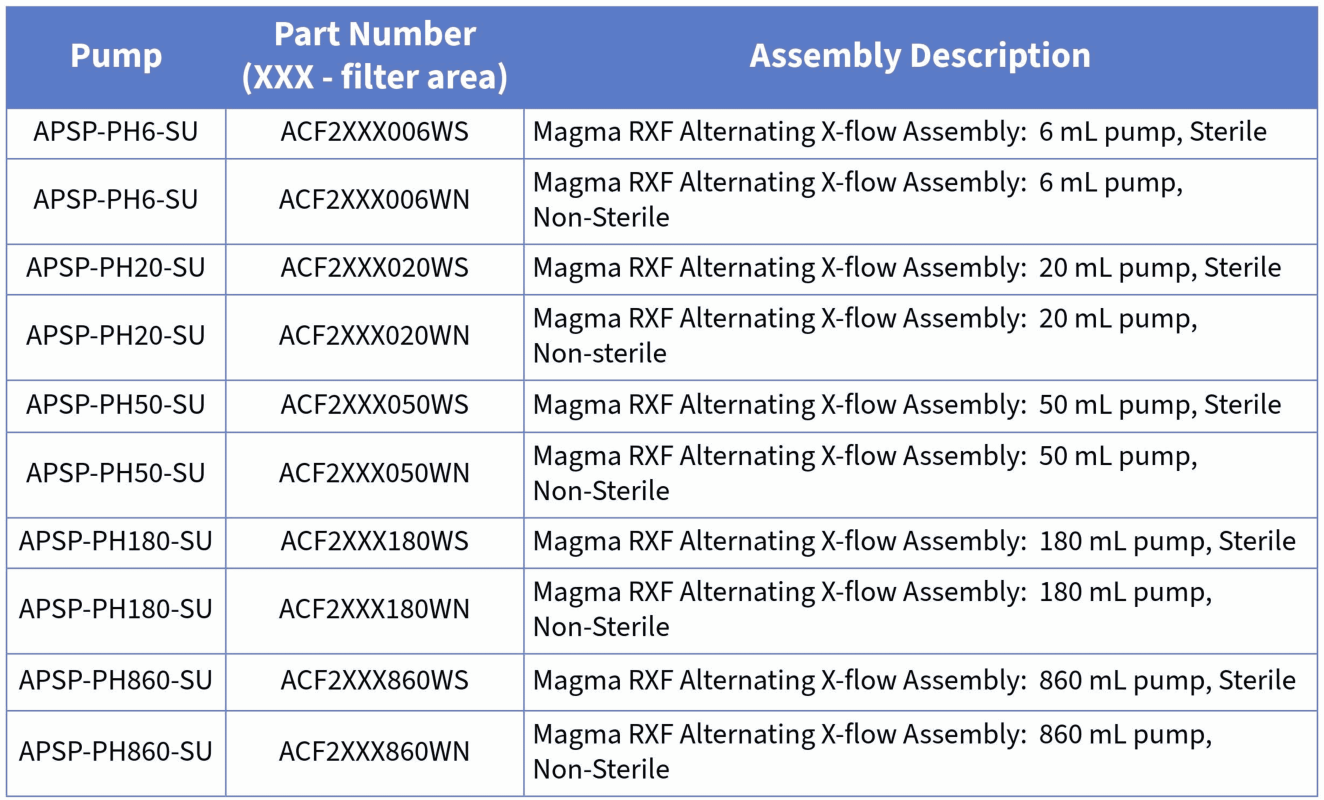

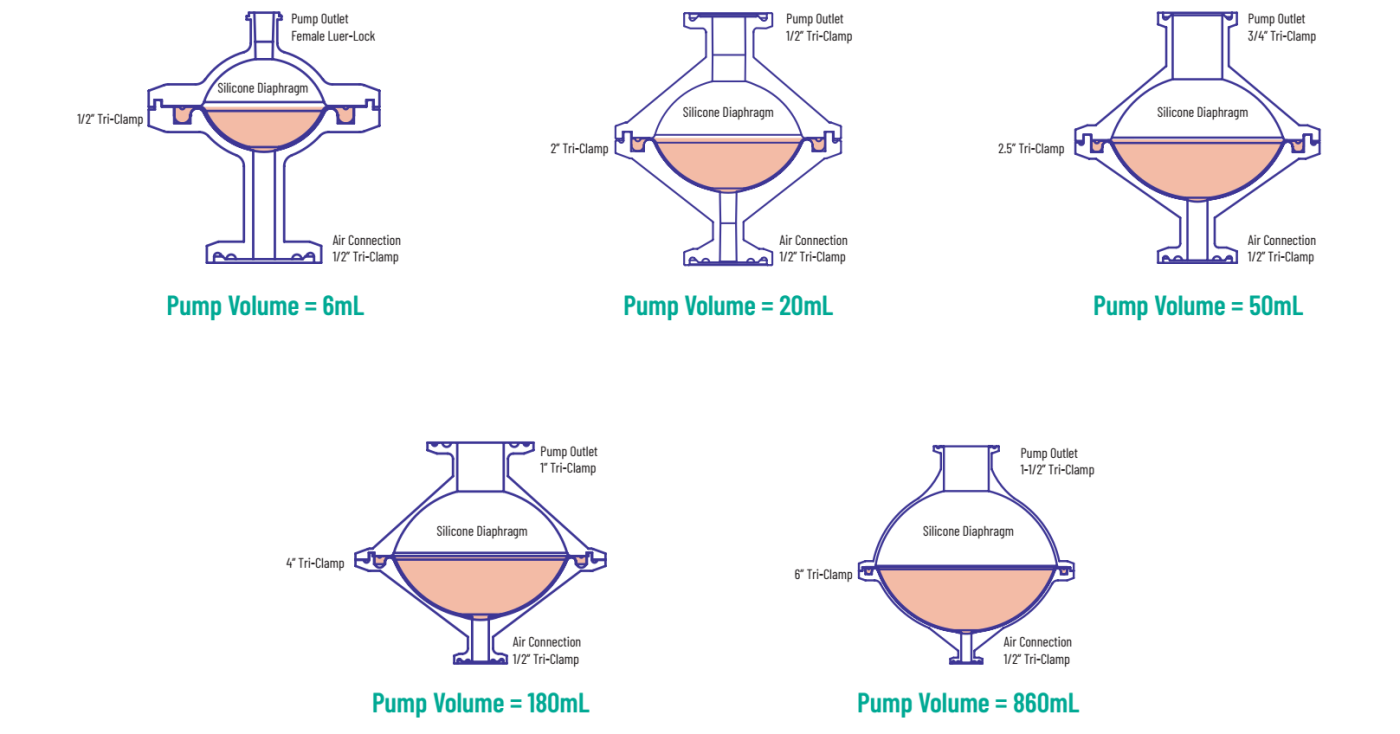

Available Pump Sizes

Product Features

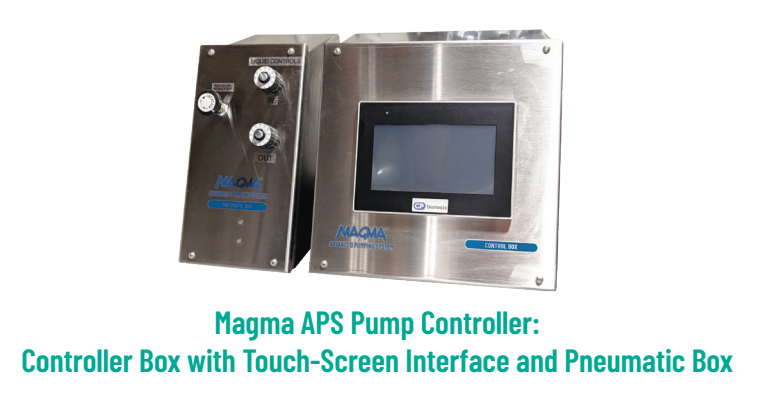

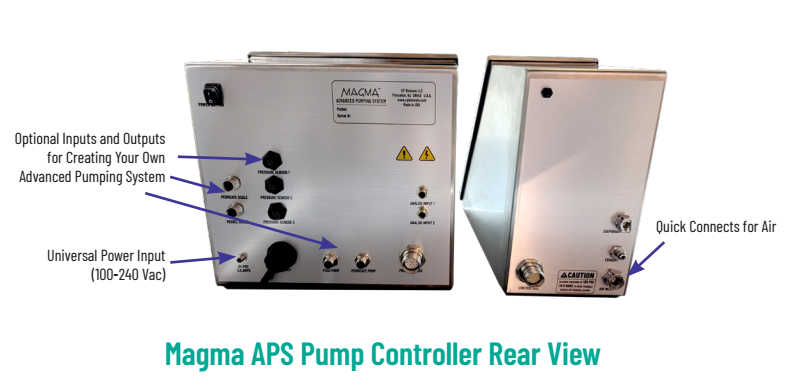

Pump Controller

Designed for Easy Use and Plug’n’Play Integration

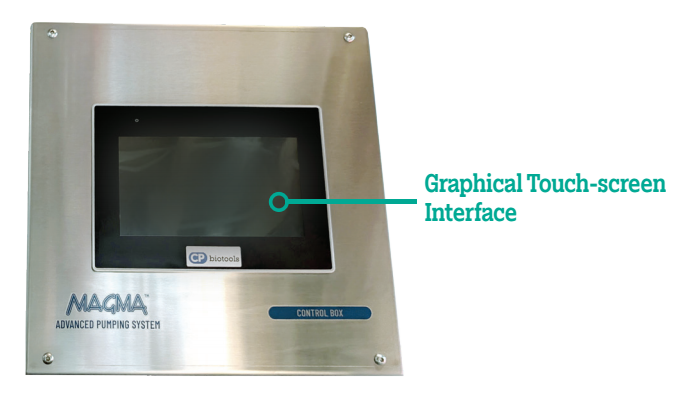

The controller comes with all the cords and hoses to be up and running in a matter of minutes. Industry standard connectors are used to assist with specific integration situations. The control box connects via a single cable to the pneumatic box which modulates the air flow in/out of the diaphragm pump. When power is initiated, the graphical touch-screen interface turns on and a screen appears to set the incoming pressure via a regulator mounted on the front panel of the pneumatic box. Once that is acknowledged the Home Screen appears. At the Home Screen you can enter the Run mode or navigate to the Set-up menus. In the Run mode there are several views that can be selected to view process conditions. The Set-up menus are easy to navigate and allows the user to set pump parameters and configure an custom advanced pumping system with the interfaced components.

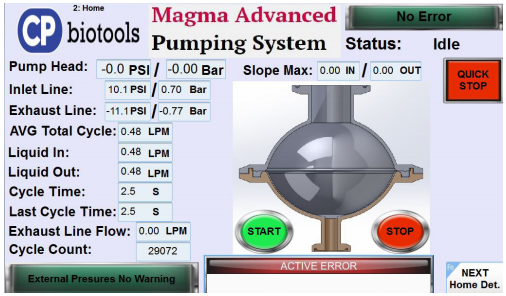

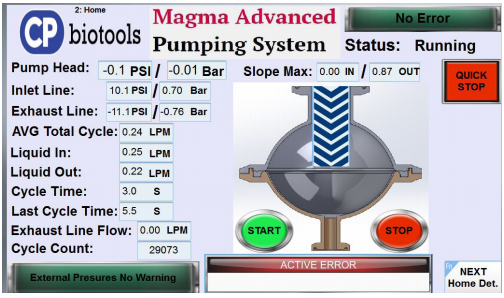

Examples of Touch-Screen Interface

Home Screen

Home Screen with pump graphic in/out flow indicator

when in Run mode

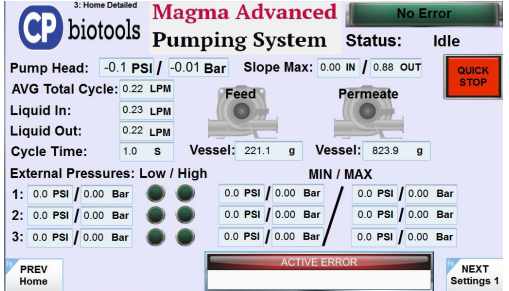

Home Detail screen- status of Pumps (highlight green when on), Scale readings, Single Use Pressure Sensor status and Min/Max since run started

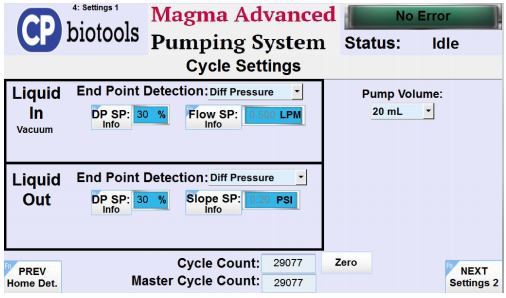

Settings Screen

Choose pump cycle endpoint setttings and pump volume

Solid Performance and Robust Designt

The pump control system is engineered with robust industrial components to ensure solid performance. The software written by

experienced engineers in the biopharm industry with full documentation and testing ensuring a path to validation. Additionally, components we selected with the highest level of assurance of supply chain availability.